Universal Springs

Welcome to

Custom spring solution for business and industries

OUR PRODUCTS

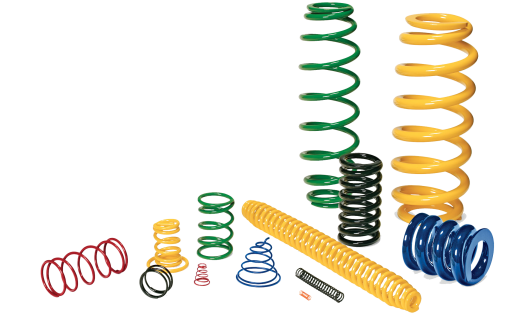

Compression Springs

Springs is a well established name in the feild of manufacturing a comprehensive range of compression Springs. Our well qualified team of professionals and workers uses the top quality raw material to manufacture these springs which provides the long working life, resistance against wear & tear, corrosion resistance and excellent strength. The compressoin springs are used in wide variety of industrial applications and can be custom made as per the specific requirements of our clients, at reasonable rates.

We manufacture and supply Compression Springs, which are an Open Coil Spring that offers resistance to a compressive force applied axially. Compression Springs are used to resist applied compression forces or to store energy in a push mode. Compression Springs have the most common configuration and are most commonly used in automotive and consumer applications. Most Compression Springs are a straight cylindrical spring made of round wire. A manufacturer of Compression Springs produces a variety of compression types, shapes, and specific specifications. Our making range includes 0.2 mm to 8.0 mm dia material of construction Spring Steel and Stainless Steel grades.

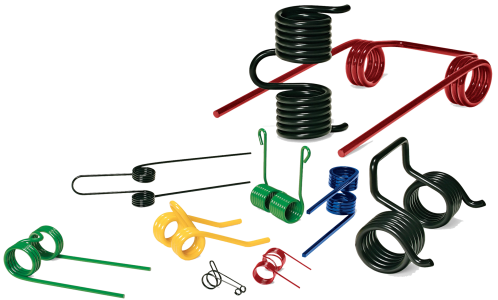

Torsion Springs

Through advanced Spring Coiling machine and a level of expertise, Spring Worksoffers Torsion Springs manufactured with the highest standards of excellence and precision. Like any other spring manufactured by us, our torsion springs and custom torsion springs are reliable and manufactured with quality and dependability in mind. Torsion springs are used in a variety of applications. For instance, common torsion springs are found in clothes pins, clipboards, and garage doors. In addition, torsion springs are also used as hinges and counterbalances in a variety of applications.

Other typical applications for torsion springs include:

- Automotive

- Irrigation

- Heavy farm equipment

- Construction equipment

Torsion Springs are helical coil springs that exert a torque or rotary force and are subjected to bending stresses. Wire diameters range from 0.2 mm to 8.0 mm, Material of construction Spring Steel and Stainless Steel grades and all types of spring wire can be utilized. Computerized test equipment monitoring insure that quality levels demanded by today's market will be met. Our fully equipped units can supply additional forming and bending operations if needed. Plating, color-coding, and special packaging can all be part of the complete product supplied. We welcome involvement at the design stage and will provide assistance or design verification as requested. Take advantage of this no-charge service!

Extension / Tension Springs

Extension Springs are close-coiled helical springs that extend under a pulling force. Extension springs with traditional or exotic hook, loop and leg configurations are easily and efficiently produced. Wire diameters range from 0.2 mm to 8.0 mm in all types of spring wire material of construction Spring Steel and Stainless Steel grades.

Shortened setup times, coupled with in-line heat treating equal cost effective quality production. Our quality monitoring process contributes to products with the low ppm reject rate demanded by today's market. The consistency and tight variation range we regularly produce is our main feature. Additional services such as plating, color-coding, and tangle-free packaging all add to the value we provide.

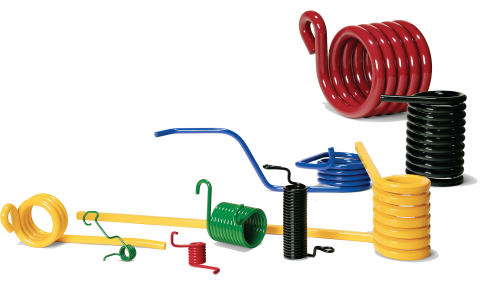

Wire Forms

Wire Forms typically are parts made from round wire that are bent to have specific angles and lengths. Most springs have a helix or spiral shape consisting of a group of coils, and wire forms. We have a complete solution for wire forming capabilities to cater your spring needs.